Intambo ye-TPU engu-95A engu-1.75mm eguquguqukayo yokunyathelisa nge-3D Izinto Ezithambile

I-Torwell FLEX TPU inobulukhuni be-Shore obungu-95 A, futhi inobude obukhulu lapho iphuka bungu-800%. Zuza ezinhlobonhlobo zezinhlelo zokusebenza nge-Torwell FLEX TPU. Isibonelo, izibambo zokunyathelisa ze-3D zamabhayisikili, ama-shock absorber, izivalo zerabha kanye nama-insoles ezicathulo.

Izici Zomkhiqizo

| Birandi | Ti-orwell |

| Izinto | I-Polyurethane ye-Thermoplastic yezinga eliphezulu |

| Ububanzi | 1.75mm/2.85mm/3.0mm |

| Isisindo sengqikithi | 1 kg/i-spool; 250g/i-spool; 500g/i-spool; 3kg/i-spool; 5kg/i-spool; 10kg/i-spool |

| Isisindo esikhulu | 1.2Kg/i-spool |

| Ukubekezelelana | ± 0.05mm |

| Lumbuso | 1.75mm(1kg) = 330m |

| Indawo Yokugcina Izinto | Yomile futhi inomoya |

| DUkusetha kwe-rying | 65˚C amahora angu-8 |

| Izinto zokusekela | Faka isicelo ngeTi-orwell HIPS, i-Torwell PVA |

| CUkuvunyelwa kokuqinisekiswa | I-CE, i-MSDS, i-Reach, i-FDA, i-TUV kanye ne-SGS |

| Iyahambisana ne | I-Reprap,Ultimaker, End3, Creality3D, Raise3D, Prusa i3, Zortrax, XYZ Printing, Omni3D, Snapmaker, BIQU3D, BCN3D, Bambu Lab X1, AnkerMaker kanye nanoma yimaphi amanye amaphrinta e-FDM 3D |

| Iphakheji | 1kg/i-spool; 8spools/ctn noma 10spools/ctn isikhwama sepulasitiki esivaliwe esine-desiccant |

Intambo ye-Torwell TPU ibonakala ngamandla ayo aphezulu kanye nokuguquguquka, njengenhlanganisela yepulasitiki nerabha.

I-95A TPU inokumelana okukhulu kokuguguleka kanye nokucindezelwa okuphansi uma kuqhathaniswa nezingxenye zerabha, ikakhulukazi lapho kugcwaliswa khona kakhulu.

Uma kuqhathaniswa nezinhlobo eziningi ze-filament ezivamile njenge-PLA ne-ABS, i-TPU kumele isebenze kancane kakhulu.

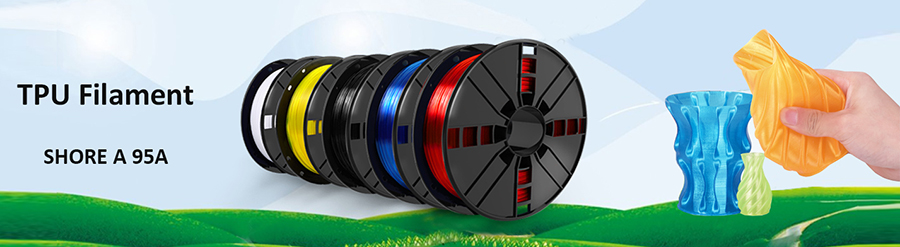

Imibala Eminingi

Umbala uyatholakala:

| Umbala oyisisekelo | Okumhlophe, Okumnyama, Okubomvu, Okuluhlaza okwesibhakabhaka, Okuphuzi, Okuluhlaza okotshani, Okumpunga, Okuwolintshi, Okubonakalayo |

| Yamukela Umbala we-PMS wekhasimende | |

Umbukiso Wemodeli

I-Torwell TPU Flexible filament kufanele iphrintwe ngesivinini esiphansi kunejwayelekile. Futhi uhlobo lwe-nozzle lokuphrinta i-Direct Drive (injini enamathiselwe ku-nozzle) ngenxa yemigqa yayo ethambile. I-Torwell TPU Flexible filament applications ifaka phakathi izivalo, ama-plug, ama-gasket, amashidi, izicathulo, ikesi lesihluthulelo se-key ring se-mobile hands-bike parts shock and wear rubber seal (Izinhlelo zokusebenza ze-Greakable Device/Protective).

Iphakheji

I-TPU ye-3D filament engu-1kg ene-desiccant ephaketheni le-vacuum.

Ibhokisi ngalinye lifakwe ebhokisini ngalinye (ibhokisi likaTorwell, ibhokisi elingathathi hlangothi, noma ibhokisi elenziwe ngokwezifiso liyatholakala).

Amabhokisi angu-8 ngebhokisi ngalinye (usayizi webhokisi ngu-44x44x19cm).

Qiniseka ukuthi i-TPU filament yakho igcinwe endaweni eyomile

Sicela uqaphele ukuthi i-TPU i-hygroscopic, okusho ukuthi ivame ukumunca amanzi. Ngakho-ke, yigcine ingangeni moya futhi ivikelwe emswakama esitsheni esivaliwe noma esikhwameni esine-dehumidifier. Uma i-TPU filament yakho ike yamanzi, ungayimisa cishe ihora elilodwa ku-70°C kuhhavini wakho wokubhaka. Ngemva kwalokho, i-filament iyomile futhi ingacutshungulwa njengentsha.

Izitifiketi:

I-ROHS; I-REACH; I-SGS; I-MSDS; I-TUV

Ulwazi Olwengeziwe

I-Torwell FLEX isebenziseka ngezindlela eziningi futhi ingasetshenziswa ezinhlobonhlobo zezinhlelo zokusebenza zokuphrinta ze-3D, okwenza kube ukukhetha okuhle kunoma ubani odinga intambo eguquguqukayo engahlangabezana nezidingo zakhe ezithile. Kungakhathaliseki ukuthi uphrinta amamodeli, ama-prototype noma imikhiqizo yokugcina, ungathembela ku-Torwell FLEX ukuthi ilethe ukuphrinta kwekhwalithi ephezulu njalo okuhlangabezana noma okudlula okulindelwe.

I-Torwell FLEX iyi-filament entsha yokunyathelisa ye-3D ezoshintsha indlela ocabanga ngayo nge-filament eguquguqukayo. Inhlanganisela yayo eyingqayizivele yokuqina, ukuguquguquka kanye nokulula kokusetshenziswa kuyenza ifaneleke kakhulu ezinhlotsheni ezahlukene zezicelo kusukela ku-prosthetics kanye namadivayisi ezokwelapha kuya kwizesekeli zemfashini. Ngakho-ke kungani ulinde? Qala nge-Torwell FLEX namuhla bese uzwa ukunyathelisa kwe-3D okungcono kakhulu okunikezwayo!

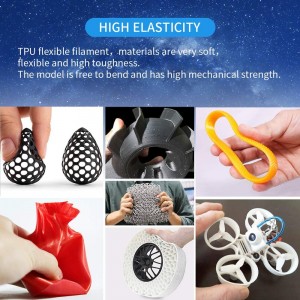

Ukuqina Okuphezulu

Ti-orwellI-TPU flexible filament iyinto ethambile futhi enwebeka njengerabha, efana ne-Flexible TPE kodwa ukuthayipha kulula futhi kunzima kune-TPE. Ivumela ukunyakaza okuphindaphindiwe noma ukushaya ngaphandle kokuqhekeka.

Ukuzivumelanisa nezimo okuphezulu

Izinto eziguquguqukayo zinesici esibizwa ngokuthi ubulukhuni beShore, okunquma ukuguquguquka noma ubulukhuni bento. I-Torwell TPU inobulukhuni beShore-A obungu-95futhi inganwebeka ngokuphindwe kathathu kunobude bayo bokuqala.

| Ubuningi | 1.21 g/cm3 |

| Inkomba Yokugeleza Kokuncibilika (g/10min) | 1.5(I-1965)190℃/2.16kg) |

| Ukuqina Kogu | 95A |

| Amandla Okudonsa | 32 MPa |

| Ukwelula Ngesikhathi Sokuphumula | 800% |

| Amandla Okugobeka | / |

| I-Flexural Modulus | / |

| Amandla Omthelela we-IZOD | / |

| Ukuqina | 9/10 |

| Ukuphrinta | 6/10 |

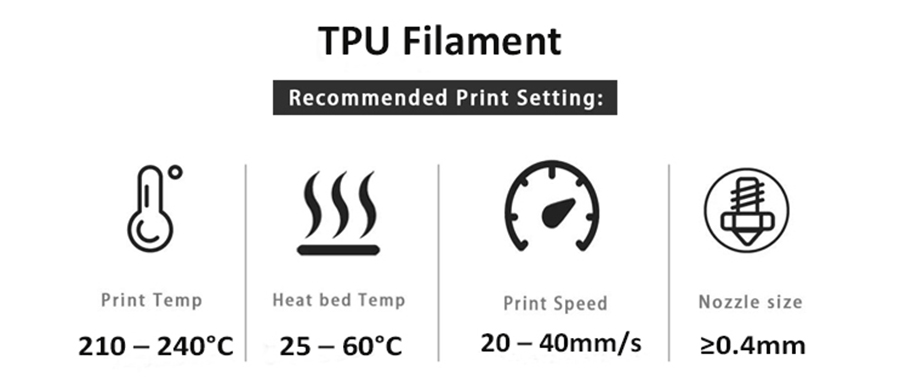

| Izinga Lokushisa Lomkhiphi (℃) | 210 – 240℃ Kunconywa ama-235℃ |

| Izinga lokushisa lombhede (℃) | 25 – 60°C |

| Usayizi We-Nozzle | ≥0.4mm |

| Isivinini saphephela | Ku-100% |

| Isivinini Sokuphrinta | 20 – 40mm/s |

| Umbhede Ofudumele | Ongakukhetha |

| Izindawo Zokwakha Ezinconyiwe | Ingilazi eneglue, iphepha lokumboza, i-Blue Tape, i-BuilTak, i-PEI |

| Izindawo Zokwakha Ezinconyiwe | Ingilazi eneglue, iphepha lokumboza, i-Blue Tape, i-BuilTak, i-PEI |

Kunconywa amaphrinta ane-extruder e-direct drive, ama-Nozzle angu-0.4 ~ 0.8mm.

Nge-Bowden extruder ungase unake kakhulu lawa macebiso:

- Phrinta kancane 20-40 mm/s Isivinini sokuphrinta

- Izilungiselelo zesendlalelo sokuqala. (Ukuphakama 100% Ububanzi 150% isivinini 50% isib.)

- Ukuhoxisa kukhutshaziwe. Lokhu kuzonciphisa umphumela wokuphrinta ongcolile, ohlanganisa izintambo noma okhipha amanzi.

- Khulisa i-Multiplier (Ongakukhetha). Ukusethwa ku-1.1 kungasiza ukubopha kahle kwe-filament. – Ukuvula ifeni yokupholisa ngemva kwesendlalelo sokuqala.

Uma unenkinga yokunyathelisa ngemicu ethambile, okokuqala, futhi okubaluleke kakhulu, yehlisa ijubane lokunyathelisa, ukusebenzisa ijubane elingu-20mm/s kuzosebenza kahle.

Kubalulekile uma ulayisha i-filament ukuyivumela ukuthi iqale ukukhipha kuphela. Uma ubona i-filament iphuma, cindezela i-nozzle iyeke. Isici sokulayisha sisunduza i-filament ngokushesha kunokushicilela okuvamile futhi lokhu kungabangela ukuthi ibambeke egiyeni le-extruder.

Futhi fakela i-filament ngqo ku-extruder, hhayi nge-feeder tube. Lokhu kunciphisa ukudonswa kwe-filament okungabangela ukuthi igiya lishelele ku-filament.