I-PLA Silk 3D filament eluhlaza okwesibhakabhaka 1.75mm

Izici Zomkhiqizo

Ti-orwellI-filament yephrinta ye-SILK 3D PLA yenzelwe ikakhulukazi ukuphrinta kwethu kwansuku zonke. Njengoba inezici zokuthungwa okukhazimulayo okusilika futhi kulula kakhulu ukuyiphrinta, noma nini lapho siphrinta imihlobiso yasekhaya, amathoyizi nemidlalo, amakhaya, imfashini, ama-prototypes, i-filament ye-Torwell SILK 3D PLA ihlala iyisinqumo sakho esihle kakhulu.

| Umkhiqizo | uTorwell |

| Izinto | izinhlanganisela ze-polymer i-Pearlescent PLA (NatureWorks 4032D) |

| Ububanzi | 1.75mm/2.85mm/3.0mm |

| Isisindo sengqikithi | 1 kg/i-spool; 250g/i-spool; 500g/i-spool; 3kg/i-spool; 5kg/i-spool; 10kg/i-spool |

| Isisindo esikhulu | 1.2Kg/i-spool |

| Ukubekezelelana | ± 0.03mm |

| Ubude | 1.75mm(1kg) = 325m |

| Indawo Yokugcina Izinto | Yomile futhi inomoya |

| Indawo Yokomisa | 55˚C amahora angu-6 |

| Izinto zokusekela | Faka isicelo nge-Torwell HIPS, i-Torwell PVA |

| Ukuvunyelwa Kwesitifiketi | I-CE, i-MSDS, i-Reach, i-FDA, i-TUV kanye ne-SGS |

| Iyahambisana ne | I-Makerbot, i-UP, i-Felix, i-Reprap, i-Ultimaker, i-End3, i-Creality3D, i-Raise3D, i-Prusa i3, i-Zortrax, i-XYZ Printing, i-Omni3D, i-Snapmaker, i-BIQU3D, i-BCN3D, i-MK3, i-AnkerMaker kanye nanoma yimaphi amanye amaphrinta e-FDM 3D |

| Iphakheji | 1kg/i-spool; 8spools/ctn noma 10spools/ctn isikhwama sepulasitiki esivaliwe esine-desiccant |

[Thuthukisa intambo ye-Silk PLA]

Ngenxa yezinto zakamuva ezinelungelo lobunikazi, i-Silk PLA Blue filament ibushelelezi futhi iyacwebezela kunanini ngaphambili. Lokho okuphrintayo kwe-3D kuzoba mhlophe njengasezithombeni, akukho ukugqama. Singochwepheshe ku-silk PLA filament futhi silethe ulwazi lokudala oluhle kakhulu lokuphrinta kwe-3D.

[Akukho Tangle futhi Kulula Ukuphrinta]

Umugqa Wokukhiqiza Omuhle Kakhulu Olawulwayo, Ukunciphisa Ukugoba Nokuncipha, Ukuqinisekisa Ukuphrinta Nge-No-Bubble kanye ne-No-Jam, Igoqwe Kahle Futhi Ayinamatheli, Kulula Ukuphrinta Futhi I-Extrusion Ebushelelezi Ngokusebenza Okuqinile Kokuphrinta.

[Ukunemba Nokuhambisana Okulinganayo]

Uhlelo lokulinganisa ububanzi be-CCD oluthuthukisiwe kanye nokulawula okuzivumelanisa nezimo ekukhiqizeni luqinisekisa lezi zintambo ze-PLA ezinobubanzi obungu-1.75 mm, Ukunemba +/- 0.03 mm okuzokunikeza ukuphrinta kwe-3D okubushelelezi.

[Kusebenza kahle futhi kuyahambisana kahle]

Njengoba eneminyaka engaphezu kwengu-11 yesipiliyoni se-3D filaments R&D, iTorwell iyakwazi ukukhiqiza zonke izinhlobo ze-filaments ngobuningi obukhulu ngekhwalithi ephezulu, okubangela ukuthi i-Torwell filament ibe ngengabizi futhi ithembeke kumaphrinta e-3D ajwayelekile, njenge-MK3, i-Ender 3, i-Monoprice FlashForge nokuningi.

Imibala Eminingi

Umbala Uyatholakala

| Umbala oyisisekelo | Okumhlophe, Okumnyama, Okubomvu, Okuluhlaza okwesibhakabhaka, Okuphuzi, Okuluhlaza okotshani, Isiliva, Okumpunga, Igolide, Okuwolintshi, Okupinki |

| Yamukela Umbala we-PMS wekhasimende | |

Umbukiso Wemodeli

Iphakheji

I-Filament ngayinye ye-Spool ipakishwe esikhwameni se-vacuum esivaliwe, ukuze ihlale yomile futhi igcine ukusebenza kwayo okuphezulu isikhathi eside

Intambo ye-PLA Silk engu-1kg ene-desiccant ephaketheni lama-vacuum

Ibhokisi ngalinye elifakwe ebhokisini ngalinye (ibhokisi likaTorwell, ibhokisi elingathathi hlangothi, noma ibhokisi elenziwe ngokwezifiso liyatholakala)

Amabhokisi angu-8 ngebhokisi ngalinye (usayizi webhokisi ngu-44x44x19cm)

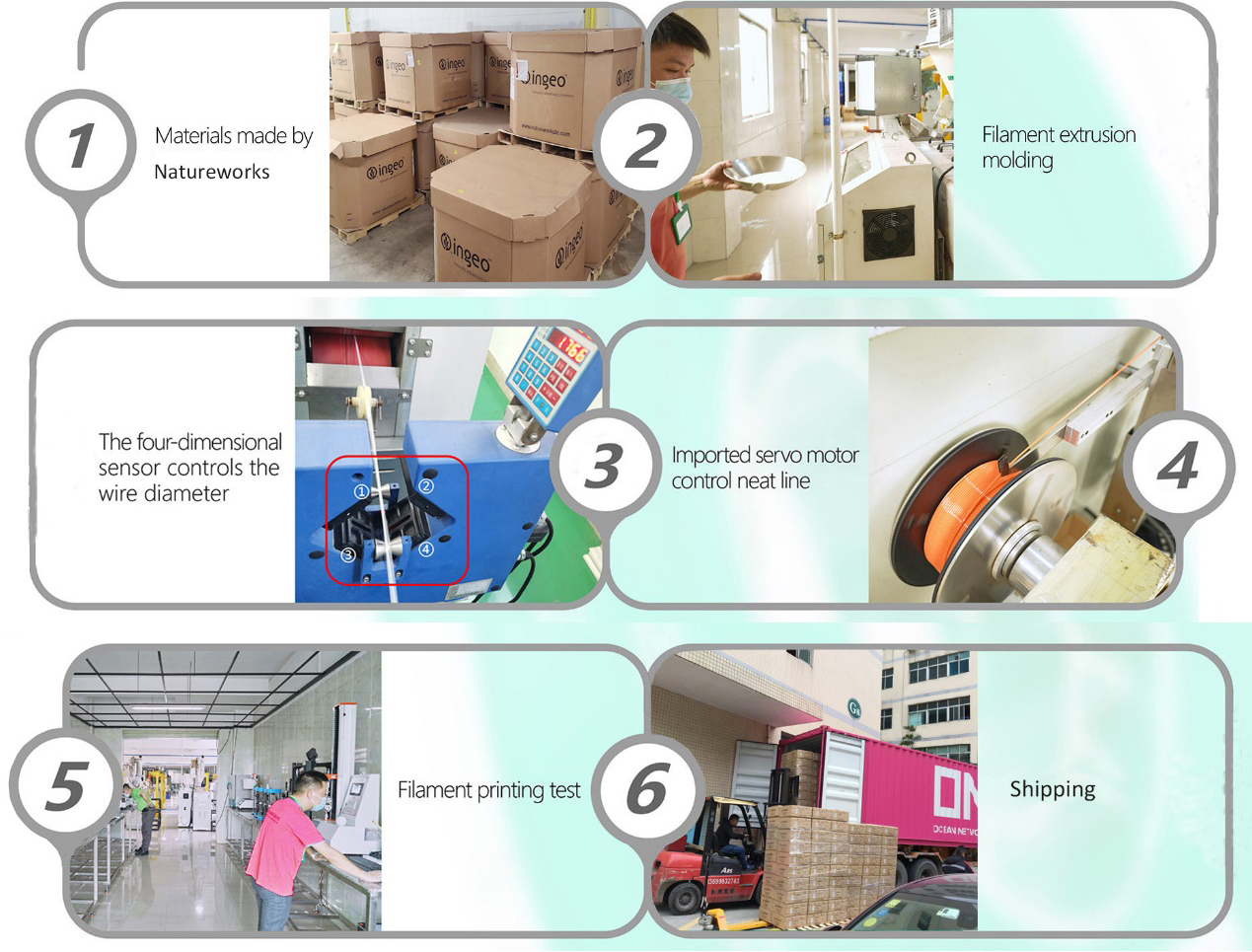

Indawo Yefektri

Imibuzo Evame Ukubuzwa

A: Qiniseka ukuthi izinga lokushisa lokuphrinta lihambisana kahle nesivinini sokuphrinta. Udinga ukulungisa izinga lokushisa lokuphrinta libe ngu-200-220℃.

A: I-Silk PLA inokwakheka kwesilika, indawo ebushelelezi kanye nokuqina okuqinile, okungafanele ukuphrinta amamodeli anokunemba okuphezulu noma amancane.

A: Ububanzi befilamenti obungaguquki, izinga lokushisa eliphansi le-nozzle kanye nokufakwa njalo kwezinhlobo ezahlukene zefilamenti kuzoholela kule nkinga. Ngakho-ke, ngaphambi kokuba uqale, hlanza i-nozzle bese ukhuphula izinga lokushisa libe nenani elifanele.

A: sizocubungula izinto ukuze sibeke izinto ezisetshenziswayo ukuze zibe manzi, bese sizifaka ebhokisini lebhokisi ukuze zivikeleke ekulimaleni ngesikhathi sokuthuthwa.

Nikeza isampula yamahhala yokuhlola. Vele usithumelele i-imeyiliinfo@torwell3d.comNoma i-Skype alyssia.zheng.

Sizokuphendula zingakapheli amahora angama-24.

| Ubuningi | 1.21 g/cm3 |

| Inkomba Yokugeleza Kokuncibilika (g/10min) | 4.7(190℃/2.16kg) |

| Izinga lokushisa lokushintshashintsha kokushisa | 52℃, 0.45MPa |

| Amandla Okudonsa | 72 MPa |

| Ukwelula Ngesikhathi Sokuphumula | 14.5% |

| Amandla Okugobeka | 65 MPa |

| I-Flexural Modulus | 1520 MPa |

| Amandla Omthelela we-IZOD | 5.8kJ/㎡ |

| Ukuqina | 4/10 |

| Ukuphrinta | 9/10 |

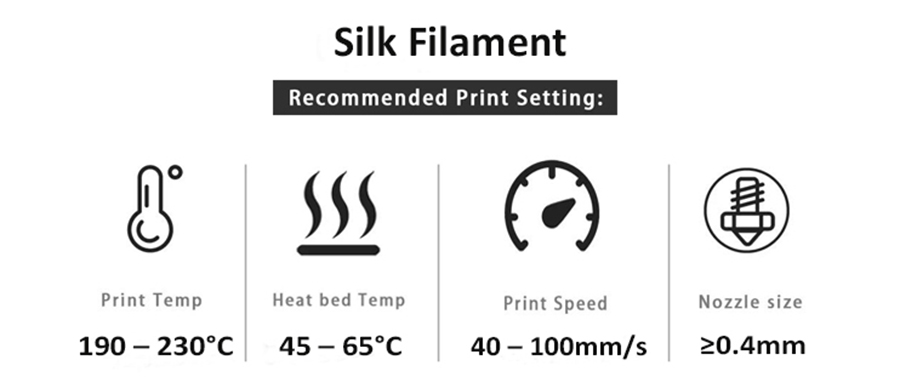

| Izinga Lokushisa Lomkhiphi (℃) | 190 – 230℃ Kunconywa 215℃ |

| Izinga lokushisa lombhede (℃) | 45 – 65°C |

| Usayizi We-Nozzle | ≥0.4mm |

| Isivinini saphephela | Ku-100% |

| Isivinini Sokuphrinta | 40 – 100mm/s |

| Umbhede Ofudumele | Ongakukhetha |

| Izindawo Zokwakha Ezinconyiwe | Ingilazi eneglue, iphepha lokumboza, i-Blue Tape, i-BuilTak, i-PEI |

Kungani imicu ingakwazi ukunamathela kalula endaweni eshisayo?

1). Hlola isethingi lokushisa ngaphambi kokuphrinta, izinga lokushisa le-SILK PLA filament cishe liyi-190-230℃;

2). Hlola ukuthi ubuso bepuleti busetshenziswe isikhathi eside, kunconywa ukusebenzisa iglue ye-PVA;

3). Uma ungqimba lokuqala lunamatheli kabi, kunconywa ukuthi kulungiswe kabusha i-substrate yokuphrinta ukuze kuncishiswe ibanga phakathi kwe-nozzle kanye ne-surface plate;